This thrust area will develop modeling/simulation tools that support the optimization of vehicle manufacturing systems. In general, all of the research areas described in the sections above are at the process level. This thrust area is intimately connected with the first three, but is focused on model development at the system level. Attention will be paid to the prediction and improvement of reliability, productivity and quality, and to the issues of flexibility and agility in vehicle manufacturing.

Current Project: Modeling Product Variety Induced Manufacturing Complexity in General Assembly (NSF GOALI)

Motivation

- Increased vehicle product variety has significant negative impact on the performance of the mixed-model assembly process.

- Very limited research has been done in assessing the impact of product variety on manufacturing system performance.

Objectives

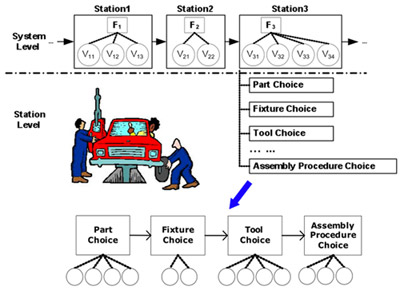

- Defining a measure of complexity based on the choices that the station operator has to make at the station level

- Understanding the relationship between complexity and system performance by collecting performance data at the stations

- Developing models for the propagation of complexity in multi-stage assembly systems to help manage complexity in system design and operation

Technical Personnel

Ningjian Huang, Ph. D.

Manufacturing Systems Lab

S. Jack Hu, Ph.D.

Professor

Mechanical Engineering

Judy Jin, Ph. D.

Associate Professor

of Industrial & Operations Engineering

Hui John Wang

Ph.D. Candidate

Andres Abad

Ph.D. Candidate, IOE